TARTLER quality for small quantity dosing Perfect mixing for the best product quality

Possible applications

Overview MDM series Small quantity dosing up to 3.5 l/min

A MDM series system is suitable for applications with a maximum of 2 flowable components made of polyurethane, epoxy resin or silicone. An output of 0.05 l/min up to 3.5 l/min can be achieved with the MDM. It is also characterized by high mixing ratio accuracy, ease of maintenance and easy, functional operation via the Siemens LOGO control system. Dosing is performed by high-precision gear pumps. Possible settings of the mixing ratio depend on the selected machine equipment.

MDM 3

Flow rate: approx. 0.7 l/min

Control: On + Off

Output adjustment:

Stepless mixing ratio adjustment:

Heating:

Volume flow measurement:

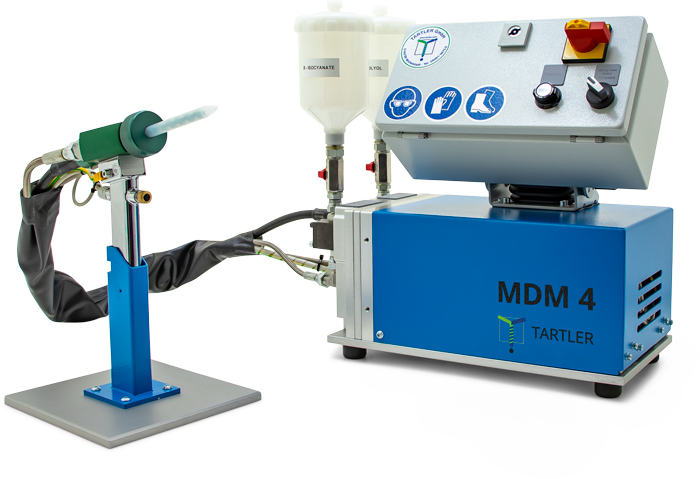

MDM 4

Flow rate: max. 1.5 l/min

Control: On + Off

Output adjustment:

Stepless mixing ratio adjustment:

Heating:

Volume flow measurement:

MDM 5

FLow rate: max. 1.5 l/min

Control: Siemens LOGO control (shot time setting, pot time alarm)

Output adjustment:

Stepless mixing ratio adjustment:

Heating:

Volume flow measurement:

MDM 6

Flow rate: max. 3,5 l/min

Control: Siemens LOGO control (shot time setting, pot time alarm small and large recirculation)

Output adjustment:

Stepless mixing ratio adjustment:

Heating:

Volume flow measurement:

Design example

MDM 3

MDM 4

MDM 5

MDM 6

Flow rate

approx. 0.7 l/min

0.5 up to 1.5 l/min

0.5 up to 1.5 l/min

0.5 up to 3.5 l/min

Control

On + Off

On + Off

Siemens LOGO control (shot time setting, pot time alarm)

Siemens LOGO control (shot time setting, pot time alarm small and large recirculation)

Output adjusment

Stepless mixing ratio adjustment

Heating

Volume flow measurement

Application example of an MDM 4

Polyurethane grouting

This video shows the MDM 4 in use for the production of flexible PU elements casted in a silicone mould.

Application example of an MDM 5

Electrical grouting

Here we show the manual electrical casting with an MDM 5. The shot time was preset via the machine control according to the moulds to be filled. After 24 hours curing time, the electrical parts are ready for use.

Application example of an MDM 6

Spray application

With this application example we demonstrate two possible spray applications with the MDM 6: Spraying through an additional mixing head valve or with a special spray attachment.

Application example of an MDM 6

Levels of automation for manual lamination

In this video, we show the possible use of an MDM system for hand laminators, e.g. in boat building and aviation. By using a metering and mixing system, the mixing ratio and shot size remain constant and the end result remains reproducible. In addition, the user is protected from material contamination.

Unified line for minimal-quantity users TARTLER offers four system solutions for the small-quantity dosing of synthetic resins

All users who work with small quantities of liquid two-component synthetic resins need to take a look at plant manufacturer TARTLER’s current portfolio. And that is because with the LC-DCM dispenser attachment and the product differentiation of the MDM series you will find four innovative solutions for the efficient dosing and mixing of epoxy resins, polyurethanes and silicone resins. Typical areas of application are prototyping, electro casting, adhesive application, as well as product development and RIM applications.

Laminating Lightweight Components Quickly and Safely TARTLER offers compact systems for small-volume application of synthetic resins

The lamination of fiber composite woven fabrics is a key shaping and joining process used in aviation, yacht construction and the manufacture of drones. Of central importance here is the reliable metering, mixing and application of the polyurethane and epoxy resins required to consolidate the fabric films. The 2C processing systems of the MDM series from TARTLER have been specifically developed for this task. Depending on the design, they are suitable for the manual or semi-automated production of laminated lightweight components for ultralight aircraft, boat hulls and drone bodies.

LC-DCM – Cartridge Mixer

Repairs, reworking or optimization of surfaces with pneumatic dispensers – now possible with dynamic mixing!

MDM – the compact solution

Compact 2-component metering and mixing systems for liquid materials in small quantities with an output of up to 3.5 l/min.

NODOPUR – the liquid solution

If the desired specifications exceed the possibilities of the compact MDM series, the NODOPUR series is the right choice.

Interested? Give us a call!

+49 6061 9672-0

You prefer writing an email?

Please use the contact form below.